- Home

- > Pumps

- > Screw Pump

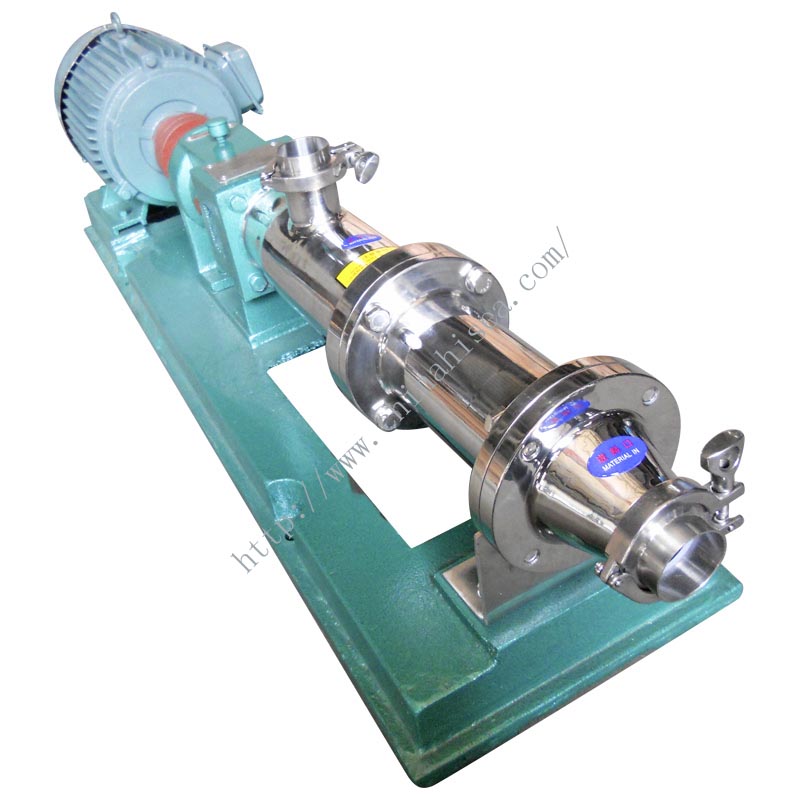

3G Series Three Screw Pump

Application

It applies to deliver clean and non-corrosive medium which has lubricating troperty at temperature beow ≤150℃、with the viscosity of 5-760cSt,The pump's working pressure range from 0.6MPa to 2.5MPa and flow capacity range from 0.6-123m3/h.

Feature

(1)Medium is delivered in axial direction continuously without agitation and pulsation.

(2)Small vibration and low noise

(3)High pressure and high efficiency

(4)Simple structure,easy disassembly and assembly

(5)Small volume and lighe weight

(6)Slight wear and long life of the pump

Structure:The pumps are sealed generally by mechanical seal and driven by the motor through the claw coupling.

Material: The driving and driven screw 16MnCrS5,40Cr,45,38CrMoALA

Pump casing:HT200,QT450-10,ZCuSn10Pl,ZG270-500

Example of pump model

Eg:3G25×4-46

3G:three screw pump

25:out-side dizmeter of the driving screw25mm

4:potch number of the screw

46:46° pitch angle of the screw

R:hezvy fuel oil

r:light fuel oil

W:high temperature heated oil

N:high visc oil

A:code of design improvement

S:double suction

According to the application modes three screw pump is divided into five series

|

Series |

Main application |

Performancescope |

|

|

Capacity m3/h |

Pre MPa |

||

|

3G |

Lub oil visc3-20oE;temp≤80℃ |

0.6-570 |

2.5 |

|

3GR |

Heavy feul lil visc3-50oE;temp≤120℃ |

0.6-570 |

2.5 |

|

3GR |

Light feul oil visc1.2-5oE;temp≤120℃ |

0.6-570 |

1.6 |

|

3GW |

High temp feul heated oil;temp≤150℃ |

0.6-363 |

1.6 |

|

3GN |

High visc oil 100oE;temp≤80℃ |

0.6-636 |

2.5 |

Performance Parameters

|

Model |

Exhaust |

Capacity Q |

Speed |

(NPSH)r |

Efficiency |

Motor |

||

|

m3/h |

L/min |

Power |

Model |

|||||

|

25×4-46 |

1.0 |

0.8 |

13 |

1450 |

4 |

62 |

0.75 |

Y802-4 |

|

2.5 |

0.6 |

10 |

60.6 |

1.5 |

Y90L-4 |

|||

|

1.0 |

2.0 |

33 |

2900 |

4.5 |

59.4 |

1.5 |

Y90S-2 |

|

|

2.5 |

1.6 |

26 |

69 |

3 |

Y100L-2 |

|||

|

30×4-46 |

1.0 |

1.6 |

26 |

1450 |

4.5 |

63.5 |

1.1 |

Y90S-4 |

|

2.5 |

1.2 |

20 |

61 |

2.2 |

Y100L1-4 |

|||

|

1.0 |

3.6 |

60 |

2900 |

5 |

60 |

2.2 |

Y90L-2 |

|

|

2.5 |

3.2 |

53 |

69 |

4 |

Y112M-2 |

|||

|

36×4-46 |

1.0 |

2.8 |

46 |

1450 |

4.5 |

66 |

2.2 |

Y100L1-4 |

|

2.5 |

2.4 |

40 |

66.5 |

4 |

Y112M-4 |

|||

|

1.0 |

6.5 |

108 |

2900 |

5 |

60.5 |

4 |

Y112M-2 |

|

|

2.5 |

6 |

100 |

72 |

7.5 |

Y132S2-2 |

|||

|

42×4-46 |

1.0 |

4.8 |

80 |

1450 |

5 |

62 |

4 |

Y112M-4 |

|

2.5 |

4.2 |

70 |

73 |

5.5 |

Y132S1-4 |

|||

|

1.0 |

10.5 |

175 |

2900 |

5.5 |

61 |

5.5 |

Y132S1-2 |

|

|

2.5 |

10 |

166 |

72 |

15 |

Y160M2-2 |

|||

|

45×4-46 |

1.0 |

6.3 |

106 |

1450 |

5 |

70 |

3 |

Y100L2-4 |

|

2.5 |

5.9 |

99 |

74 |

7.5 |

Y132M-4 |

|||

|

1.0 |

13.5 |

225 |

2900 |

5.5 |

60 |

7.5 |

Y132S2-2 |

|

|

2.5 |

13 |

217 |

75 |

15 |

Y160M2-2 |

|||

|

60×4-46 |

1.0 |

15.5 |

255 |

1450 |

5 |

71.3 |

11 |

Y160M-4 |

|

2.5 |

14.5 |

245 |

74 |

15 |

Y160L-4 |

|||

|

1.0 |

32 |

533 |

2900 |

5.5 |

63 |

18.5 |

Y160L-2 |

|

|

2.5 |

31.5 |

525 |

77 |

37 |

Y200L2-2 |

|||

|

70×2-46 |

0.6 |

24 |

400 |

1450 |

5 |

71 |

7.5 |

Y132M-4 |

|

1.0 |

23.5 |

390 |

75 |

11 |

Y160M-4 |

|||

|

1.6 |

22.5 |

370 |

76 |

15 |

Y160L-4 |

|||

|

70×4-46 |

1.0 |

24.5 |

408 |

1450 |

5 |

72.5 |

18.5 |

Y180M-4 |

|

2.5 |

23.5 |

392 |

79 |

30 |

Y200L-4 |

|||

|

80×2-46 |

0.6 |

36.5 |

608 |

1450 |

5 |

72 |

11 |

Y160M-4 |

|

1.0 |

35 |

594 |

75.5 |

18.5 |

Y180M-4 |

|||

|

1.6 |

34.5 |

575 |

76.5 |

22 |

Y180L-4 |

|||

|

80×4-46 |

1.0 |

37 |

617 |

1450 |

5.5 |

72 |

30 |

Y200L-4 |

|

2.5 |

35 |

590 |

78.1 |

45 |

Y225M-4 |

|||

|

100×2-46 |

0.6 |

72.5 |

1208 |

1450 |

5 |

73 |

22 |

Y180L-4 |

|

1.0 |

71 |

1183 |

77 |

37 |

Y225S-4 |

|||

|

1.6 |

60.5 |

1158 |

79 |

45 |

Y225M-4 |

|||

|

100×4-46 |

1.0 |

72.5 |

1208 |

1450 |

5.5 |

73 |

55 |

Y250M-4 |

|

2.5 |

70 |

1165 |

78.5 |

75 |

Y280S-4 |

|||

|

S100×3-27 |

0.6 |

72 |

1196 |

1450 |

6 |

62 |

22 |

Y180L-4 |

|

1.6 |

70 |

1160 |

72 |

55 |

Y250M-4 |

|||

|

2.5 |

69 |

1145 |

74 |

75 |

Y280S-4 |

|||

|

S120×3-27 |

0.8 |

123 |

2055 |

1450 |

6 |

74.5 |

55 |

Y250M-4 |

|

1.5 |

120 |

2010 |

76 |

90 |

Y280M-4 |

|||

|

2.5 |

115 |

1920 |

78.5 |

132 |

Y315M-4 |

|||

Society certificates

CONTACT WITH US NOW