Ballast Water Management System

1. General Introduction

Around the world approximately 3 to 5 billion tons of ballast water is transferred via ships each year, introducing aquatic invasive species into new environment, posing serious threats to maritime ecosystems, aquatic economy and human health.

The transfer of ballast water cannot be avoided since ballast water is absolutely essential to the safe and efficient operation of modern shipping. But the transportation of non-native species can be eliminated by means of appropriate treatment of ballast water.

The International Maritime Organization (IMO) has adapted the International Convention for the Control and Management of Ship’s Ballast Water and Sediments, 2004, which mandates all ships that carry ballast water install treatment system by the required year depending on their ballast tank capacity and the year being built.

2. Hazards of Ballast Water

Loading ballast water is the necessary method during ship sailing. When loading ballast water, organisms in seawater could be carried into ballast tanks and discharged to the destination sea area. Ballast water in ships from one sea area to another could cause the invasion of harmful aquatic organisms and pathogens. The unlimited ballast water discharging could cause serious ecological, economic and public heath impact to the receiving environment. The invasion of alien organisms had been listed by GEF as one of the four hazards to the ocean.

In order to control the invasion of harmful aquatic organisms and pathogens in ballast water effectively, the International Maritime Organization (IMO) has developed the International Convention and Management of Ship’s Ballast Water and Sediments in 2004. The convention came into force since 2009 and requires that new ships must install ballast water treatment systems and this requirement is also suitable for the existing ships. Meanwhile, the convention had set regulation D-2 which regulated the category and the quantity of the surviving organisms in treated ballast water.

3. IMO D-2 Standards for Discharge of Ballast Water

|

Organism Type |

Required Regulation |

|

Organisms,≥50μm minimum dimension |

<10cells/ m3 |

|

Organisms, <50μm and ≥10μm minimum dimension |

<10cells/ml |

|

Toxicogenic Vibrio cholerae (serotypes O1 and O39) |

<1cfu/100ml,or <1cfu/g(wet weight)of zooplankton samples |

|

Escherichia coli |

<250cfu/100ml |

|

Intestinal Enterococci |

<100cfu/100ml |

4. Schedule for Installation of Ballast Water Treatment System

| Year Built | BW Capacity(m3) | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | |

|

Newly-built Ship |

<2009 | <5,000 | D1 | D2 | ||||||

|

<2012 >2009 |

≥5,000 | D1 | D2 | |||||||

| >2012 | ≥5,000 | D2 | ||||||||

| Spot Ship | <2009 | 1,500-5,000 | D1 | D2 | ||||||

| <2009 |

<1,500 >5,000 |

D1 | D2 | |||||||

|

D1-Ballast Water Exchange Standard |

||||||||||

|

D2-Installation of Ballast Water Treatment System Required |

5. Treatment Technology

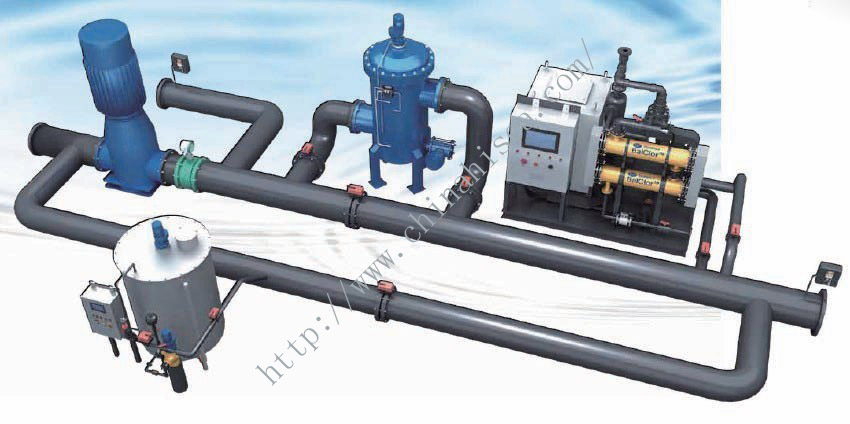

The BWMS features two-stage process, applying efficient automatic filtration to remove larger organisms and sediments followed by powerful medium pressure UV unit to disinfect and inactivate smaller plankton, bacteria and pathogens.

Adopting totally chemical-free process, the BWMS best suits the demand of ship by effectively avoiding the uptake or discharge of harmful organisms but generating no toxic substance to environment and human health or corrosion contribution to ballast system.

Ballast water is treated going through the complete process (filter followed by UV reactor) at ballast water intake and re-treated at discharge through the UV reactor only (filter bypassed). The UV irradiation of ballast water again during de-ballasting ensures that any bacterial regrowth that may have occurred in the ballast tanks is fully disinfected before discharge.

6. Specification of the BWMS System

|

Model |

Capacity (m3/hr) |

Dimension (mm,L×W×H) |

Weight (kg) |

|

B150 |

150 |

2410×1265×1955 |

550 |

|

B250 |

250 |

3010×1265×2115 |

750 |

|

B300 |

300 |

3010×1265×2115 |

750 |

|

B500 |

500 |

3600×2015×3250 |

1250 |

|

B600 |

600 |

3650×2250×3250 |

1280 |

|

B750 |

750 |

3740×2280×3810 |

2850 |

|

B1000 |

1000 |

4165×2415×3845 |

3250 |

|

B1200 |

1200 |

3650×4500×3250 |

3560 |

|

B1500 |

1500 |

3740×4560×3810 |

5700 |

|

B2000 |

2000 |

4165×4830×3845 |

6500 |

|

B3000 |

3000 |

4165×7245×3845 |

9750 |

|

B4000 |

4000 |

4165×9660×3845 |

13000 |

|

B5000 |

5000 |

4165×12075×3845 |

16250 |

|

B6000 |

6000 |

4165×14490×3845 |

19500 |

7. Automatic back-flushing Filter in Front

The automatic self-cleaning filter serves to remove larger organisms and sediment particles, improving the transparency of water, and hence the effectiveness of UV irradiation.The filter is designed to automatically back-flush itself at the end of each ballasting or de-ballasting operation, and when a timer is triggered or preset differential pressure caused by solids built up on filter screen is reached.

This automatic back-flushing mechanism keeps the filter screen clean and provides reliable, non-stop operation at high sediment loads. All organisms and particles removed by the filter are continuously returned to the sea at ballasting site. The filter is bypassed during the de-ballasting operation.

Specification & Advantages

- Removing large organisms over 50um

- Enhancing UV light transmission

- Reducing sediment in ballast tanks

- Low pressure drop

- Automatic back flushing

- Continuous filtering operation

- Vertical or horizontal installation

8. UV Disinfection

Our BWMS adopts medium pressure ultraviolet (UV) as a means of disinfection.Unlike chemical disinfectant, this purely physical disinfection process uses nothing but UV light to deactivate or damage the DNA of organisms, killing them or making reproduction impossible without any side effect.

The medium pressure lamps that our BWMS utilizes produce polychromatic UV output across the entire spectrum of germicidal curve. Taking into account the various poor water quality challenges at high flow rates, the powerful medium pressure lamps are regarded as a better solution for ballast water treatment application rather than low pressure lamps.

The medium pressure lamps are installed to be oriented perpendicular to fluid flow, which results in high performance and compact size for easy installation.

Specification & Advantages

Long life span medium pressure lamps

- Compact size for easy installation & maintenance

- Automatic wiping mechanism to ensure reliable lamp performance

- On-line UV intensity sensor for monitoring and control of consistent UV dosage,

- Electronic ballast for optimal lamp power supply

-Proven disinfection technology on land and shipboard application for water treatment

- Easy and safe operation without side effect

- No chemicals added or toxic by-products generated

- No corrosion contribution to ballast system

- Not affected by variations in ballast water salinity in different harbors

9.Control Panel

The entire BWMS is controlled by a PLC (programmable logic controller) control panel with in-touch screen mounted on it. The PLC system monitors and controls all components (filter, UV, automatic valves, if required) and keeps the UV unit running at optimal status.

All operations and indications can be viewed on in-touch screen and the system can be easily integrated into ship control system to allow for operation and monitoring in control room.

Specification of Control Panel

- PLC based

- Human Machine Interface with in-touch screen

- All operations and data displayed

- Data logging for 24 months

- Visual & audible alarm

- Flexible interface with ship control system

10. Module Design

11. Shipboard Testing

Society certificates

CONTACT WITH US NOW