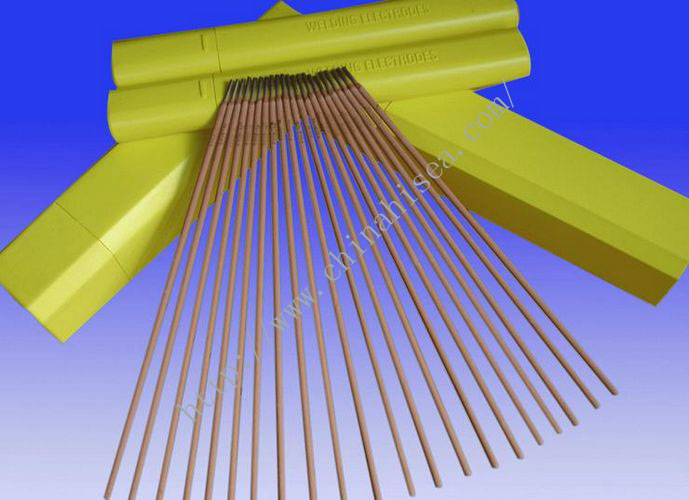

E7028 carbon steel weldin rods

GB:E5028

AWS:E7028

Current:Used for downhand welding and flat fillet welding on carbon steel and low-alloy steel structures, such as 16Mn, 09Mn2Si, 09Mn2V and A, B, D and E steel for ships, etc.

|

Introduction: J507Fe16 is a kind of high efficiency carbon steel electrode with iron powder low-hydrogen natrium type coating. The deposition efficiency can reach approximately 160%. DCRP (Direct Current Reversed Polarity). Suitable for downhand welding and flat fillet welding. The deposited metal has excellent mechanical properties. It has stable arc, fewer spatters, good slag detachability and beautiful appearance of weld. |

|||||||||||||||||||||

|

|

|||||||||||||||||||||

|

Chemical Composition of Deposited Metal (%)

|

|||||||||||||||||||||

|

Mechanical Properties of Deposited Metal

|

|||||||||||||||||||||

|

Diffusible Hydrogen Content in Deposited Metal: ≤8.0ml/100g(Glycerine Hydrogen Test) |

|||||||||||||||||||||

|

X-ray Radiographic Inspection: ⅡDegree |

|||||||||||||||||||||

|

Reference Current (DC+)

|

|||||||||||||||||||||

|

Instructions: 1.The electrodes must be baked under 350℃ for an hour before welding and used as soon as baking is completed. 2.The stains on the work pieces, such as oil stains, rust, moisture, etc., must be cleared away before welding. 3.When welding, operation with short arc and no weaving is suitable. |

|

||||||||||||||||||||

Society certificates

CONTACT WITH US NOW