- Home

- > Cable

- > Power Cable

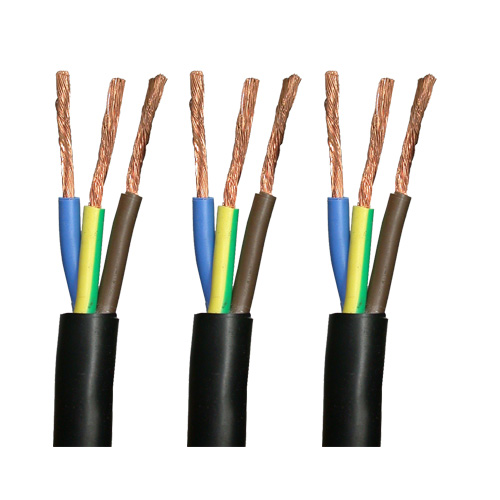

Plastic insulated power cable

Plastic insulated power cable

Plastic insulated power cable application

The insulating layer of Plastic insulated power cable is extruded plastic power cable. Commonly used plastic polyvinyl chloride, polyethylene, cross-linked polyethylene. Plastic cable simple structure, easy processing, light weight, easy installation, laying, without laying drop restrictions. It is widely used for medium and low voltage cables, and replace the sticky greaseproof paper impregnated cables trend. Its biggest disadvantage is the branch of the breakdown, which limits its use in higher voltage.

This cable can be suitable for power transmission and distribution lines rated voltage for 0.6/1kv to 26/35kv.

Plastic insulated power cable service condition

Rated power frequency voltage U0/U:0.6/1KV~26/35KV.

PVC insulated power cable Max. permissible continuous operating temperature of the conductor should not exceed 70℃,XPLE insulated power cable permissible continuous operating temperature of the conductor should not exceed 90℃.

Max Short–circurrt temperature of conductor shall not exceed 250℃.(5s maximum duration)

The installation temperature should not below 0℃

bending radius of a single core should not less than 20 times of the cable diameter. bending radius of a three-core cable should not less than 15 times of the cable diameter.

Plastic insulated power cable standards

The flame-retardant properties of cable comply with the requirements of Category A specified inGB12666.5-90 .

The flame-retardant properties of lower halogen cable comply with requirements of Category A specified in GB12666.5-90 and requirements specified in GB/T17650.2-1998

The flame-retardant properties of halogen free cable comply with requirements of category A specified in GB12666.5-90 and in GB/T17650.2-1998.and GB/T17651-1998.

The product is manufactured according to the standard of GB12706-91、GB12666.5-90、GB/T17650-1998 and GB/T17651-1998 or IEC and DIN and ICEA.

Plastic insulated power cable construction

Plastic insulated power cable technical parameters

| Nominal Cross-section area(mm2) | 1 | 1.5 | 2.5 | 4 | 6 | 10 | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 | 185 | 240 | 300 | 400 | 500 | 630 | 800 | 1000 |

| Insulation thickness(mm) at 0.6/1KV | 0.8 | 0.8 | 0.5 | 1 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 1.6 | 1.6 | 1.8 | 2.0 | 2.2 | 2.4 | 2.6 | 2.8 | 2.8 | 2.8 | 3.0 |

| Insulation thickness(mm) at 3.6/6KV |

|

|

|

|

|

3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 |

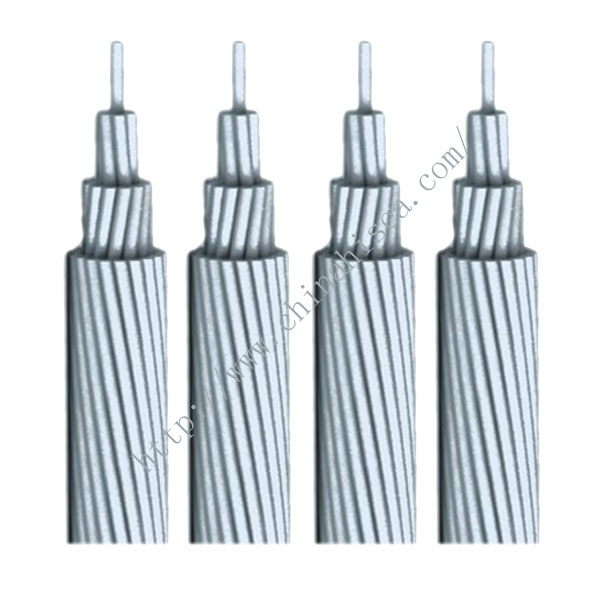

Plastic insulated power cable show

Plastic insulated power cable sample

Extruding

Cable waiting for test

Society certificates

CONTACT WITH US NOW