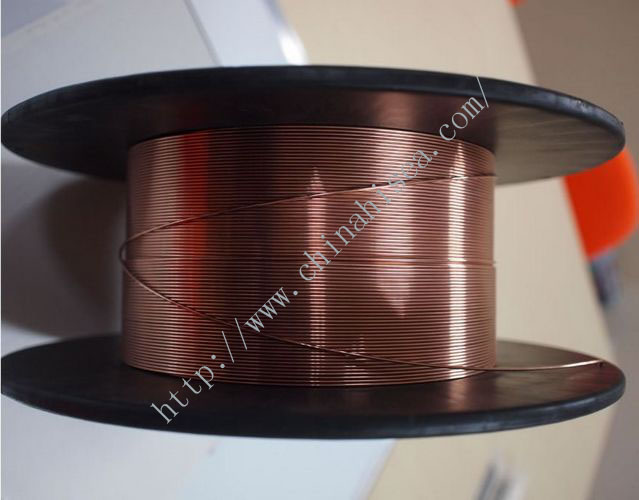

JQ.SJ301C Silicon-manganese Type Acid Sintered Flux

AWS:F6A0-EL8 F7A0-EM12

Current:If used together with appropriate wires (such as H08A), they can be used for welding hull structures, and also used for welding general structural steel, boiler steel, pipeline steel, etc. Able to be used for multi-pass welding, single pass welding by bot

Main Applications:

JQ.SJ301C |

According with GB F4A2-H08A F5A2-H08MnA Corresponding with AWS F6A0-EL8 F7A0-EM12 DIN BOS198AC10SKM |

||||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

Reference Composition of Flux(%)

|

|||||||||||||

|

Mechanical Properties of Deposited Metal

|

|||||||||||||

|

Instructions: 1.The fluxes should be baked under 300~350℃ for 2 hours before using. 2.The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away before welding. |

|||||||||||||

Society certificates

CONTACT WITH US NOW