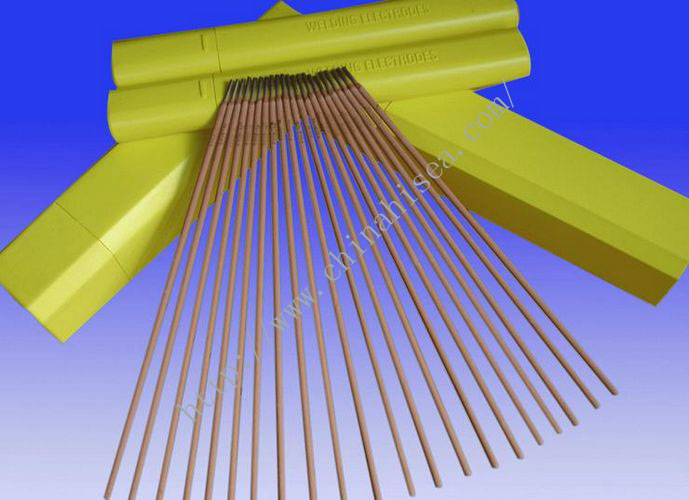

JQ.H10MnSi Submerged-arc Welding Wire

JQ.H10MnSi

GB:H10MnSi

AWS:EM13K

Current:Used together with fused flux 350 or sintered flux 101. Used for both high speed welding and filling welding on 50kg class base metals. Mostly used for welding boilers, pressure vessels, bridges, ships, etc.

Main Applications:

AWS:EM13K

Current:Used together with fused flux 350 or sintered flux 101. Used for both high speed welding and filling welding on 50kg class base metals. Mostly used for welding boilers, pressure vessels, bridges, ships, etc.

Main Applications:

JQ.H10MnSi |

According with GB H10MnSi Corresponding with AWS EM13K |

||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

Chemical Composition of Welding Wire(%)

|

|||||||||||||||||||||||||

|

Mechanical Properties of Deposited Metal

|

|||||||||||||||||||||||||

|

Wire Size

|

|||||||||||||||||||||||||

Society certificates

CONTACT WITH US NOW