- Home

- > Cable

- > Special Cable

Prefabricated Branch Cable

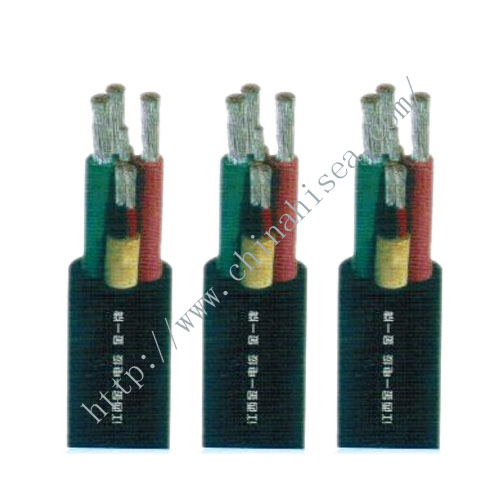

Prefabricated Branch Cable

Safety in power supply

1 Trunk cable conductor without joint has good continuity and reduces trouble spots.

2 Branch joint made through whole course mechanical processing in the factory greatly reduces poor quality phenomena due to manmade factors.

3 Branch joint of rational structure and made through advanced LYZ workmanship has little contact resistance and cannot be affected by thermal expansion and cold shrinkage.

4 Pressing mould jacket processed in short time avoids variation of contact resistance owing to oxidization of copper core at the joint position which is exposed in the air for long time.

5 Branch joint has strict technical standard, inspection requirement, and quality control system as well.

Simpleness in installation, low requirement to environment, and convenience in construction

1 Small land-covering area facilitates effective use of floorage.

2 Low requirement to environment and low requirement to installation precision.

3 Simpleness in installation and low requirement to installation technology.The installation period is short only 1/10 or 1/20 of that of bus duct. The labor strength for installation is small.

4 Small bending radius greatly reduces installation difficulty and reduces space size.

Excellent shock resistance, air tightness, water proofing quality and flame resistance

1 Excellent shock resistance.Generally, the bus duct joint connected mechanically will be loose upon the wall is shocked. But GQFZ series prefabricated branch cable will not be affected. Especially passing through building sedimentation slots, no measure is need.

2 Excellent air tightness and water proofing quality. It can supply power normally in damp environment and be laid in the open air or underground.

3 NH type prefabricated branch cable can remain normal power supply operation for 90 min under flaming condition.

Free of maintenance

1 High once opening rate of prefabricated branch cable after being installed according to stipulated ways.

2 While normally work, prefabricated branch cable system is free of maintenance generally.

Prefabricated Branch Cable Model

|

Number

|

Name

|

Model

|

|||

|

Single Core

|

3 Cores Twisted type

|

4 Cores Twisted type

|

5 Cores Twisted type

|

||

|

1

|

PVC insulated andf sheathed prefabricated branch cable

|

FZ-VV

|

FZ-VV-3

|

FZ-VV-4

|

FZ-VV-5

|

|

2

|

PVC insulated andf sheathed flame retardant prefabricated branch cable

|

FZ-ZRVV

|

FZ-ZRVV-3

|

FZ-ZRVV-4

|

FZ-ZRVV-5

|

|

3

|

PVC insulated andf sheathed fireproof prefabricated branch cable

|

FZ-NHVV

|

FZ-NHVV-3

|

FZ-NHVV-4

|

FZ-NHVV-5

|

|

4

|

XLPE insulated PVC sheathed prefabricated branch cable

|

FZ-YJV

|

FZ-YJV-3

|

FZ-YJV-4

|

FZ-YJV-5

|

|

5

|

XLPE insulated PVC sheathed flame retardant prefabricated branch cable

|

FZ-ZRYJV

|

FZ-ZRYJV-3

|

FZ-ZRYJV-4

|

FZ-ZRYJV-5

|

|

6

|

XLPE insulated PVC sheathed fireproof prefabricated branch cable

|

FZ-NHYJV

|

FZ-NHYJV-3

|

FZ-NHYJV-4

|

FZ-NHYJV-5

|

Prefabricated Branch Cable Technical Parameter

|

Conductor

|

Insulation Thickness

mm

|

Sheath thickness

mm

|

Outer Diameter

mm

|

Weight

kg/km

|

A.C Test Voltage

kV/5Min.

|

20℃

Maximum DC resistance(Ω/km)

|

*1

40℃

ampacity

A

|

Impedance

Z Ω/km

|

Note

|

||||

|

Nominal

Cross-section

mm2

|

No.&Dia. or type No/mm

|

Dia.

mm

|

cosθ=1

|

cosθ=0.9

|

cosθ=0.8

|

Unbalanced load carrying capacity

(40 ℃)A

|

|||||||

|

6

10 |

7/1.04

7/1.35 |

3.1

3.7 |

0.7

0.7 |

1.4

1.4 |

8.0

8.5 |

105

150 |

3.5

3.5 |

3.08

1.83 |

61

85 |

3.93

2.33 |

3.61

2.17 |

3.25

1.96 |

58

80 |

|

16

25 35 50 70 |

Round tight

Pressure wire |

4.7

5.9 7.0 8.5 10.1 |

0.7 |

1.4

1.4 1.4 1.4 1.4 |

9.5

11.0 12.0 13.5 15.0 |

210

310 410 555 760 |

3.5

3.5 3.5 3.5 3.5 |

1.15

0.727 0.524 0.387 0.268 |

113

150 180 265 290 |

1.47

0.93 0.67 0.49 0.34 |

1.39

0.90 0.67 0.51 0.37 |

1.27

0.84 0.63 0.48 0.36 |

105

140 170 230 265 |

|

95

120 150 185 240 |

11.7

13.2 14.7 16.4 18.6 |

1.1

1.2 1.4 1.6 1.7 |

1.4

1.6 1.6 1.6 1.7 |

17.0

19.0 21.0 23.0 26.0 |

1020

1260 1570 1920 2470 |

3.5

3.5 3.5 3.5 3.5 |

0.193

0.153 0.124 0.0991 0.0754 |

345

405 460 530 640 |

0.25

0.20 0.16 0.13 0.10 |

0.28

0.24 0.20 0.18 0.15 |

0.28

0.24 0.21 0.19 0.16 |

325

380 435 500 595 |

|

|

300

400 500 600 |

20.8

24.1 26.9 30.2 |

1.8

2.0 2.2 2.4 |

1.8

2.0 2.2 2.4 |

29.0

32.0 36.0 40.0 |

3090

4080 5080 6390 |

3.5

3.5 3.5 3.5 |

0.0601

0.0470 0.0366 0.0283 |

725

845 970 1120 |

0.08

0.06 0.05 0.04 |

0.13

0.12 0.10 .09 |

0.15 |

685

795 920 1070 |

|

|

Conductor

|

Insulation Thickness

mm

|

Sheath Thickness

mm

|

O.D.

mm

|

Weight

kg/km

|

A.C Test Voltage

kV/5Min

|

20℃

Maximum DC resistance of (Ω/km)

|

*1

40℃Ampacity

A

|

Impedance Z Ω/km

|

Note

|

||||

|

Nominal Cross-section

mm2

|

No.&Dia. or Type

No/mm

|

Dia.

mm

|

cosθ=1

|

cosθ=0.9

|

cosθ=0.8

|

Unbalanced load carrying capacity

(40 ℃ )A

|

|||||||

|

6

10 |

7/1.04

7/1.35 |

3.1

3.7 |

0.7

0.7 |

1.4

1.4 |

19.3

20.5 |

430

620 |

3.5

3.5 |

3.14

1.87 |

53

72 |

4.01

2.38 |

3.68

2.21 |

3.31

2.00 |

45

61 |

|

16

25 35 50 70 |

Round tight

Pressure wire |

4.7

5.9 7.0 8.5 10.1 |

0.7 |

1.4

1.4 1.4 1.4 1.4 |

23.0

26.5 29.0 33.0 36.5 |

860

1270 1680 2270 3110 |

3.5

3.5 3.5 3.5 3.5 |

1.17

0.742 0.534 0.395 0.273 |

95

125 150 185 230 |

1.50

0.95 0.68 0.50 0.35 |

1.41

0.92 0.68 0.51 0.37 |

1.29

0.85 0.63 0.49 0.36 |

6814

105 130 160 205 |

|

95

120 150 185 240 |

11.7

13.2 14.7 16.4 18.6 |

1.1

1.2 1.4 1.6 1.7 |

1.4

1.6 1.6 1.6 1.7 |

41.0

46.0 51.0 55.5 63.0 |

4170

5150 6410 7840 10080 |

3.5

3.5 3.5 3.5 3.5 |

0.197

0.156 0.126 0.101 0.0769 |

280

325 380 440 535 |

0.25

0.20 0.16 0.13 0.10 |

0.28

0.24 0.20 0.17 0.15 |

0.28

0.24 0.21 0.18 0.16 |

250

290 335 385 455 |

|

|

300

400 500 600 |

20.8

24.1 26.9 30.2 |

1.8

2.0 2.2 2.4 |

1.8

2.0 2.2 2.4 |

70.0

77.5 87.0 96.5 |

12610

16650 20730 26080 |

3.5

3.5 3.5 3.5 |

0.0601

0.0470 0.0366 0.0283 |

625

735 865 1010 |

0.08

0.06 0.05 0.04 |

0.13

0.11 0.10 0.09 |

0.14 |

525

605 700 800 |

|

Prefabricated Branch Cable Show

Society certificates

CONTACT WITH US NOW