- Home

- > Cable

- > Special Cable

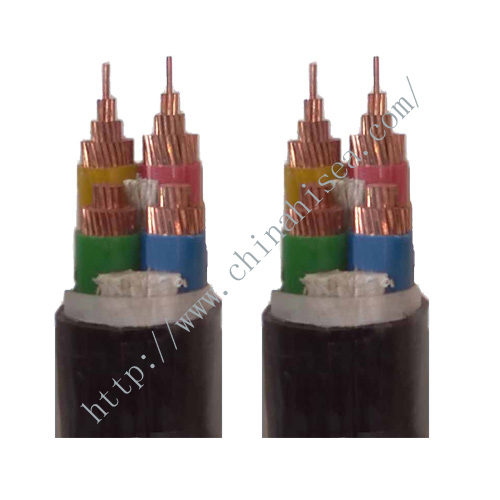

Rubber insulated Nitrile Sheath Lead cable

Rubber insulated Nitrile Sheath Lead cable

Rubber insulated Nitrile Sheath Lead cable Application

This model is suitable for transformers,motors,power distribution equipment and a variety of equipment lead wire.

Rubber insulated Nitrile Sheath Lead cable Structure

1.tinned copper conductor

2.isolation layer ( if any )

3.rubber insulation layer

4.nitrile rubber sheath layer

Rubber insulated Nitrile Sheath Lead cable Test

wires should be able to withstand the Impregnation test, via wire

130 ± 5 ℃, 5 hours constant temperatures , the immersion temperature of 50 ± 5 ℃

1032 paint for 30 minutes, remove the drip dry , and then by 130 ± 5 ℃, 48 hours

constant temperatures , and finally the wire wound on a specified diameter rod ,

wire sheathing layer should be no cracking , embrittlement , and

stickiness

Rubber insulated Nitrile Sheath Lead cable Specification

JEFR 500V|

Nominal Cross-section (mm2)

|

Conductor Core Structure (mm)

|

Nominal Insulation Thickness

(mm) |

Nominal Sheath Thickness

(mm) |

Max. Cable O.D.

(mm) |

Reference Weight(kg/km)

|

20℃Conductor Resistance≤(Ω/km)

|

|

|

Single Core Number

|

Dia.

|

||||||

|

0.5

|

28

|

0.15

|

0.6

|

0.8

|

4.3

|

20

|

38.5

|

|

0.75

|

42

|

0.15

|

0.6

|

0.8

|

4.5

|

24

|

25.7

|

|

1.0

|

32

|

0.20

|

0.6

|

0.8

|

4.7

|

28

|

18.9

|

|

1.5

|

48

|

0.20

|

0.6

|

0.8

|

5.0

|

35

|

12.6

|

|

2.5

|

19

|

0.41

|

0.8

|

1.0

|

6.2

|

57

|

7.59

|

|

4

|

19

|

0.52

|

0.8

|

1.0

|

6.8

|

76

|

4.54

|

|

6

|

19

|

0.64

|

0.8

|

1.0

|

4.5

|

100

|

3.00

|

|

10

|

49

|

0.52

|

1.0

|

1.2

|

10.0

|

178

|

1.78

|

|

16

|

49

|

0.64

|

1.0

|

1.2

|

11.2

|

243

|

1.18

|

|

25

|

98

|

0.58

|

1.0

|

1.4

|

13.7

|

372

|

0.716

|

|

35

|

133

|

0.58

|

1.0

|

1.4

|

14.8

|

471

|

0.528

|

|

50

|

133

|

0.68

|

1.2

|

1.6

|

17.1

|

647

|

0.384

|

|

70

|

189

|

0.68

|

1.2

|

1.6

|

19.6

|

879

|

0.270

|

|

95

|

259

|

0.68

|

1.4

|

1.6

|

21.9

|

1160

|

0.197

|

|

120

|

259

|

0.76

|

1.6

|

1.8

|

24.6

|

1451

|

0.158

|

|

150

|

320

|

0.76

|

1.8

|

2.2

|

29

|

1911.5

|

0.132

|

|

185

|

395

|

0.76

|

1.8

|

2.2

|

32

|

2268.65

|

0.108

|

|

240

|

513

|

0.76

|

2.2

|

3

|

35

|

3010

|

0.0817

|

|

300

|

641

|

0.76

|

2.4

|

3.5

|

38

|

3770

|

0.654

|

Rubber insulated Nitrile Sheath Lead cable Show

Society certificates

CONTACT WITH US NOW