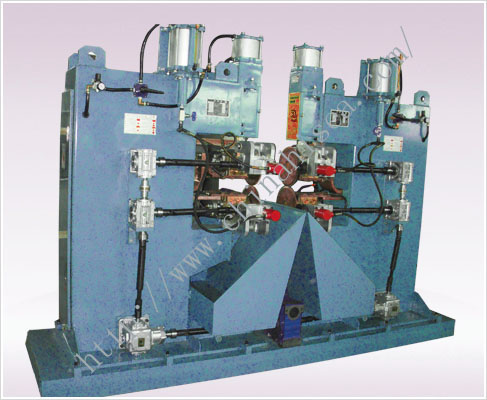

Three-phase secondary rectifier spot welder

Three-phase secondary rectifier spot welding machine:

By using high-power silicon diode groups rectifiern in the secondary of transformer, AC turns into DC.

Used for mterial:Low carbon steel, coated steel, stainless steel, heat-resistant alloy, copper, aluminum and its alloy outside, titanium, niobium, zirconium and rare metal and multi-layer steel plate,

Applied to industries: automotive, aviation, aerospace, nuclear, and radio, etc.

Advantage:

1. DC circuit makes small inductive reactance, thus power factor is highter than mchine of AC.

2. Dc heating anoids heat loss cause by the electric amplitude, and splash by large peak current,so input capacity is smaller at same thickness.

3. No electromagnetic force betwen two electrode arm, electrode pressure is stable.

4. 3 phasse input power does not affect the balance of power grid.

Reference data:

|

parameters |

HSDZ-75

|

HSDZ-100 |

HSDZ-150

|

HSDZ-200

|

|

|

parameters /KVA |

75 |

100 |

150 |

200 |

|

|

lod rate /% |

50 |

50 |

50 |

50 |

|

|

power |

380V/50HZ/2 |

380V/50HZ/2 |

380V/50HZ/2 |

380V/50HZ/2 |

|

|

Secondary no-load voltage /V |

7 |

8.6 |

11.8 |

14 |

|

|

max shot circuit current /KA |

22 |

30 |

35 |

40 |

|

|

arm extension /mm |

380 |

380 |

410 |

410 |

|

|

Electrode working stroke /mm |

80 |

80 |

80 |

80 |

|

|

Rated electrode pressure /N |

7300 |

7300 |

12000 |

18000 |

|

|

bleed pressure /MPa |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

cooling water flow / 1/h |

|

|

|

|

|

|

cooling water pressure MPa |

0.15-0.3 |

0.15-0.3 |

0.15-0.3 |

0.15-0.3 |

|

|

Maxi welding ability /mm |

mild steel |

4.0+4.0 |

4.5+4.5 |

5.0+5.0 |

4.5+4.5 |

|

aluminum |

1.0+1.0 |

1.5+1.5 |

2.0+2.0 |

2.5+2 |

|

Society certificates

CONTACT WITH US NOW