Substructure

Features of Substructure:

Four types: slingshot (dually raised- type)/ swing up/block package/box-on-box.

Slingshot Substructure:

The drill floor and the Equipment on it can be installed at low position; and the mast is erected up to vertical position while the drill floor keeps low-position, then the drill floor and the mast are lifted integrally to working position.

There are two hydraulic cylinders equipped on top layer of the substructure; they can be used for buffering and regulating while lifting the drill floor, and as a pushing force while laying down the drill floor.

It is designed into modules. For land way and railway transportation, the substructure can be disassembled into small pieces and also into large pieces for oil field transportation as well.

4 There is standby interface at the bottom layer of the substructure for integral trailer or horizontally moving device; the mast, drawworks and BOP device etc can be moved integrally. It meets the requirement of quick movement and drilling cluster well.

Swing up Substructure:

1 Parallelogram lifting structure is used, so drill floor and the equipments on it can be installed at low position, and lifted by the drawworks force.

2 There are two hydraulic cylinders equipped on top layer of the substructure; they can be used for buffering and regulating while lifting the drill floor, and as a pushing force while laying down the drill floor.

3 Less power is needed and stable for lifting.

Block Package Substructure:

1 The structural type is “tall front and low back”. The front of the substructure is taller, meeting the requirement of standard BOP installation. The back of the substructure is lower, meeting the installation requirement of heavier power equipment and drive device.

2 The main parts are big components with good rigidness, so they are stable.

Box-on-box Substructure:

1 The main structure is big box-on-box structure, the location between each layers is fixed by combination of concave and convex blocks.

2 It is simple, quick and stable for its installation.

Specifications of Substructure:

|

Type |

Swing up type substructure |

Swing up type substructure |

Box-on-box type substructure |

Slingshot type substructure |

Block package substructure |

Slingshot type substructure |

|

Model |

DZ158/6-S |

DZ180/6-S |

DZ170/8.6-XD |

DZ225/7.5-G |

DZ225/7.5-K |

DZ315/9-G |

|

Drill floor height (m) |

6 |

6 |

8.6 |

7.5 |

7.5 |

9 |

|

Clear height under RT beam (m) |

4.3 |

4.3 |

7.223 |

6.26 |

6.32 |

7.62 |

|

RT beam load (kN) |

1580 |

1800 |

1700 |

2250 |

2250 |

3150 |

|

Setback load (kN) |

870 |

1080 |

1080 |

1105 |

1440 |

1800 |

|

Mast bottom span (m) |

-- |

-- |

7.5 |

8 |

8 |

8 |

|

Type |

Block package substructure |

Block package substructure |

Slingshot type substructure |

Block package substructure |

Integral swing up substructure |

Swing up type substructure |

|

Model |

DZ315/7.5-K |

DZ315/9-K |

DZ450/9-G |

DZ450/9-K |

DZ450/10.5-S |

DZ675/12-S |

|

Height of drill floor (m) |

7.5 |

9 |

9 |

9 |

10.5 |

12 |

|

Clear height under RT beam (m) |

6.26 |

7.62 |

7.6 |

7.727 |

9.227 |

10 |

|

RT beam load(kN) |

3150 |

3150 |

4500 |

4500 |

4500 |

6750 |

|

Setback load(kN) |

1800 |

1800 |

2520 |

2520 |

2520 |

3250 |

|

Mast bottom span (m) |

9.11 |

9.11 |

9 |

9.11 |

8.5 |

10 |

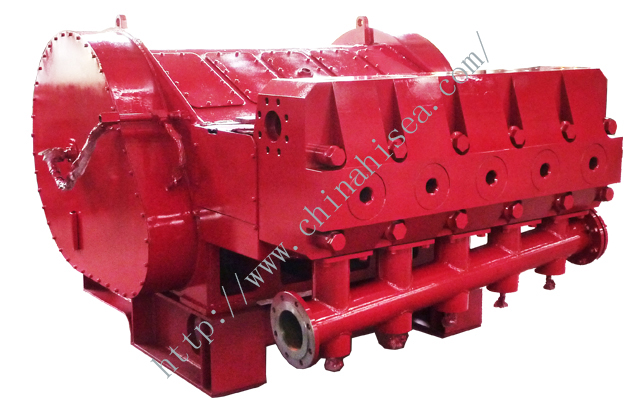

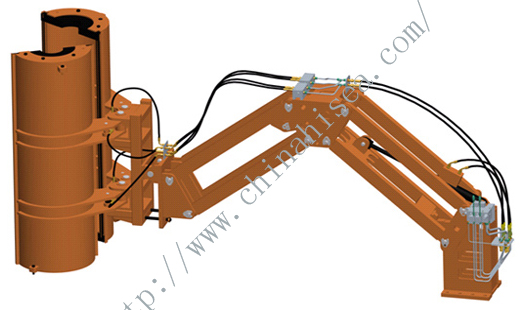

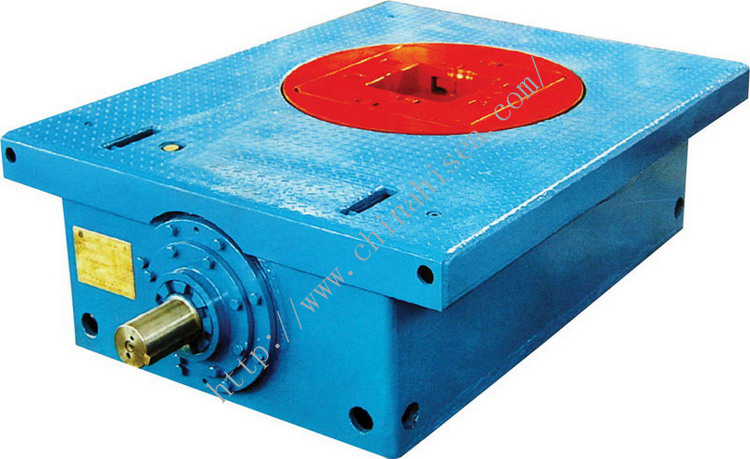

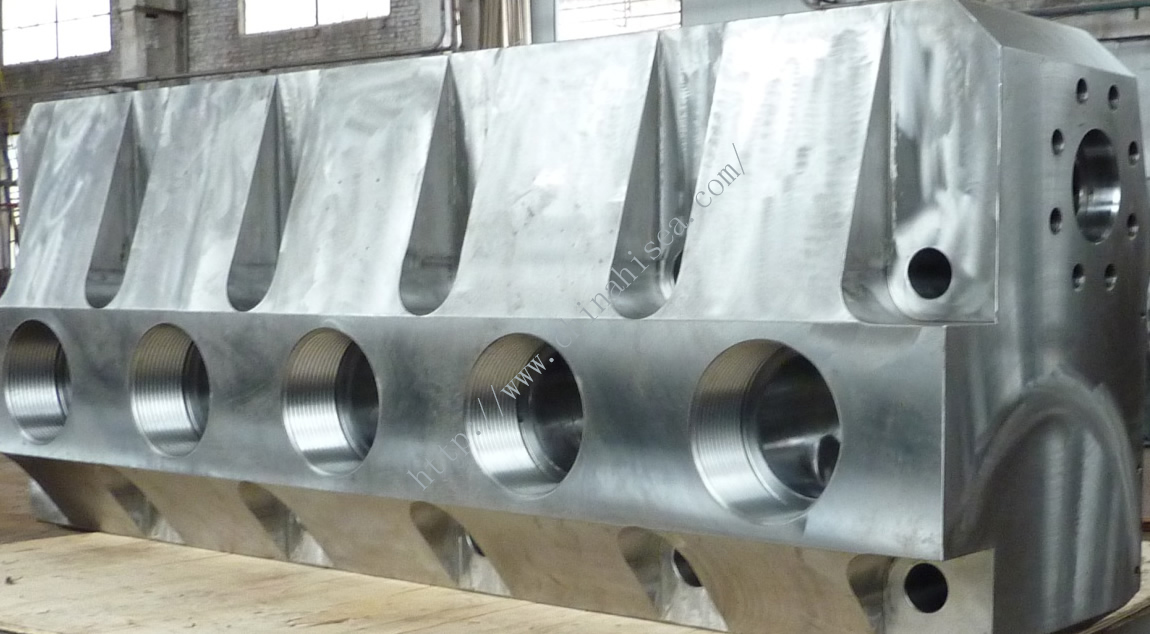

Pictures of Substructure:

Substructure

Substructure - Close Shot

For further and more detailed product information, you are welcome to contact us at any time in any of the following ways.

---------------------------------

Contact:

Aiphen ZHANG

Sales Manager

Chongqing Hi-Sea Marine Equipment Import & Export Co., Ltd.

Address: Unit 20-5, Building of Chongqing General Chamber of Commerce, No.2, Hongjin Street, Yubei District, Chongqing 401147, China

E-mail: oildept@hiseamarine.com

Society certificates

CONTACT WITH US NOW