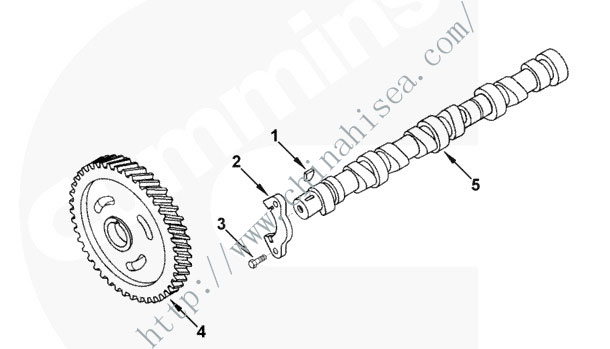

Auto engine camshaft

Auto engine camshaft:

In internal combustion engines with pistons, the camshaft is used to operate poppet valves. It then consists of a cylindrical rod running the length of the cylinder bank with a number of oblong lobes protruding from it, one for each valve. The cam lobes force the valves open by pressing on the valve, or on some intermediate mechanism as they rotate. in four stroke engine valves are opened by "camshaft"

Automotive Material

Camshafts can be made out of several different types of material. These include:

Chilled iron castings: this is a good choice for high volume production. A chilled iron camshaft has a resistance against wear because the camshaft lobes have been chilled, generally making them harder. When making chilled iron castings, other elements are added to the iron before casting to make the material more suitable for its application.

Billet Steel: When a high quality camshaft is required, engine builders and camshaft manufacturers choose to make the camshaft from steel billet. This method is also used for low volume production. This is a much more time consuming process, and is generally more expensive than other methods. However the finished product is far superior. When making the camshaft, CNC lathes, CNC milling machines and CNC camshaft grinders will be used. Different types of steel bar can be used, one example being EN40b. When manufacturing a camshaft from EN40b, the camshaft will also be heat treated via gas nitriding, which changes the micro-structure of the material. It gives a surface hardness of 55-60 HRC. These types of camshafts can be used in high-performance engines.

Depending on the location of the camshaft, the cams operate the valves either directly or through a linkage of pushrods and rockers. Direct operation involves a simpler mechanism and leads to fewer failures, but requires the camshaft to be positioned at the top of the cylinders. In the past when engines were not as reliable as today this was seen as too much bother, but in modern gasoline engines the overhead cam system, where the camshaft is on top of the cylinder head, is quite common.

Camshafts can be made out of several different types of material. These include:

Chilled iron castings: this is a good choice for high volume production. A chilled iron camshaft has a resistance against wear because the camshaft lobes have been chilled, generally making them harder. When making chilled iron castings, other elements are added to the iron before casting to make the material more suitable for its application.

Billet Steel: When a high quality camshaft is required, engine builders and camshaft manufacturers choose to make the camshaft from steel billet. This method is also used for low volume production. This is a much more time consuming process, and is generally more expensive than other methods. However the finished product is far superior. When making the camshaft, CNC lathes, CNC milling machines and CNC camshaft grinders will be used. Different types of steel bar can be used, one example being EN40b. When manufacturing a camshaft from EN40b, the camshaft will also be heat treated via gas nitriding, which changes the micro-structure of the material. It gives a surface hardness of 55-60 HRC. These types of camshafts can be used in high-performance engines

Society certificates

CONTACT WITH US NOW