JQ.SJ101G Fluoride-basic Type Sintered Flux

JQ.SJ101G

GB:F4A4-H08MnA F5A4-H10Mn2

AWS:F6A4-EM12

Current:If used together with some wires like H10Mn2, H08C, etc., they can be used for welding joints of spiral welded pipes of oil and gas pipelines. If used together with H08C, they are especially suitable for welding X65 and X70 spiral welded pipes, and the we

Main Applications:

JQ.SJ101G

|

According with GB F4A4-H08MnA F5A4-H10Mn2

Corresponding with AWS F6A4-EM12

DIN BF B165AC12MHP5

|

|

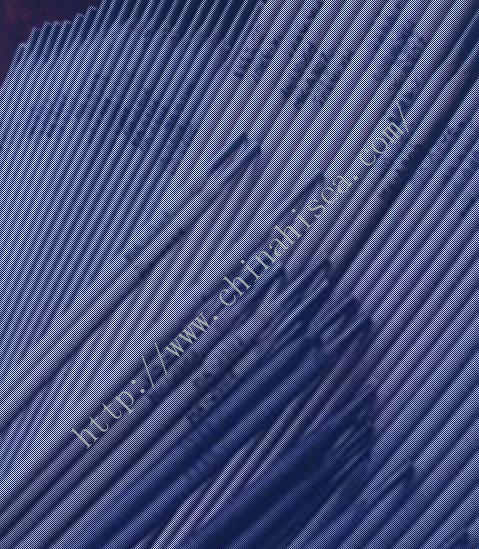

Introduction: JQ.SJ101G is a kind of fluoride-basic type sintered flux specially used for spiral welded pipes. The alkalinity is approximately 1.8. Light gray round grains. The granularity is 2.0~0.28mm (10~60 meshes/inch). It has excellent welding performance, higher welding speed, stable arc, good slag detachability and beautiful appearance of weld. Because it is produced by special technology, it has complete metallurgical reactions when welding. The deposited metal is pure and it has higher low temperature impact toughness. AC/DC. When welding with direct current, the wire should be connected to the positive terminal.

|

|

Uses: If used together with some wires like H10Mn2, H08C, etc., they can be used for welding joints of spiral welded pipes of oil and gas pipelines. If used together with H08C, they are especially suitable for welding X65 and X70 spiral welded pipes, and the welding speed can reach over 70m/h.

|

Reference Composition of Flux(%)

|

S

|

P

|

SiO2+TiO2

|

CaO+MgO

|

Al2O3+MnO

|

CaF2

|

|

~0.010

|

~0.030

|

15~35

|

25~35

|

20~30

|

18~25

|

|

Mechanical Properties of Deposited Metal

|

Rm

|

ReL或Rp0.2

|

A

|

KV2(J)

|

|

(MPa)

|

(MPa)

|

(%)

|

-20℃

|

-40℃

|

|

560~650

|

≥450

|

≥24

|

≥120

|

≥90

|

|

Instructions:

1.The fluxes should be baked under 300~350℃ for 2 hours before using.

2.The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away before welding.

|

CONTACT WITH US NOW