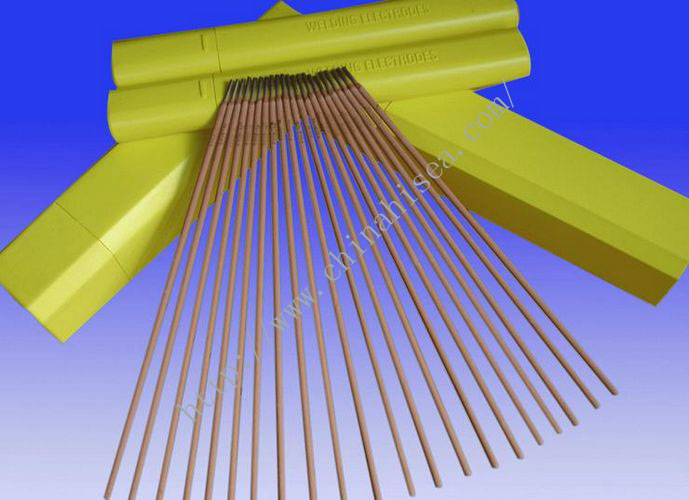

JQ.YD212-1 Gas-shielded Solid Welding Wire

JQ.YD212-1

GB:

AWS:

Current:Suitable for the situation of impact-resistance and medium wear. Used for single layer or multi-layer surfacing welding and repairing of the surfaces of all kinds of worn-out parts, such as gears, dredge buckets, mining machinery, etc.

Main Applications:

AWS:

Current:Suitable for the situation of impact-resistance and medium wear. Used for single layer or multi-layer surfacing welding and repairing of the surfaces of all kinds of worn-out parts, such as gears, dredge buckets, mining machinery, etc.

Main Applications:

JQ.YD212-1 |

|||||||||

|

|

|||||||||

|

|

|||||||||

|

Chemical Composition of Deposited Metal (%)(CO2Shielding Gas)

|

|||||||||

|

Hardness of Surfacing Layer: HRC≥50 |

|||||||||

|

Reference Current (DC+)

|

|||||||||

|

Instructions: 1.The oil stains and rust on the weldments should be cleared away. 2.When welding, the gas flow rate is generally 20~25L/min. 3.When welding with flux-cored welding wires, the extension elongation should be 15~25mm. 4.Large work pieces should be appropriately preheated to about 300℃ before surfacing welding. 5.The humidity of the welding wire storerooms should be preserved below 60%. 6.It is not suitable for non-vacuum-packed welding wires to be stored for more than half a year, and it is not suitable for vacuum-packed welding wires to be stored for more than a year. |

|||||||||

Society certificates

CONTACT WITH US NOW