Marine Oil Water Separator Factory

1. Marine Oil Water Separator (OWS):

An oil water separator (OWS) is a piece of shipboard or in general waste water treatment equipment that separates oil from oily waste water such as bilge water before the waste water is discharged.

The YWC series oil water separator is equipped with the 15 ppm oil content alarm device, type tested and approved in accordance with IMO Resolution MEPC.107(49).

The IMO Resolution MEPC.107 (49) has been adopted on 18th July 2004 and applies to all oil water separators and 15-ppm alarm devices to be installed onboard ships on or after 1st January 2005.

2. Marine Oil Water Separator (OWS) Factory:

The OWS factory is one of the enterprise under China Shipbuilding Industry Corporation. Which now has employee more than 200 people, the total asset investment is more than 12million and the area is more than 16000 m2, self-contained production, strong technical force, advanced detection means.

From 1982, our products have been sold out all over the world, such as Malaysia, Singapore, Germany, Italy, French, Korea, Japan, Australia, Argentina, India, Yemen, Ghana, Nigeria etc. Deeply general customers high praise.

The factory is a complex that gathers design, developing and producing. Over the years mainly engaged in 15ppm Oil Water Separator, Sewage Treatment Plant, Pressure Water Tank, Sewage Holding Tank, Positive pressure fire air-breathing apparatus, Emergency escape breathing device, Protective clothing for fire-fighting, Personal equipment for fire-fighter, Simple protection suit, Monitor, Portable foam applicator, Light series(lifejacket light, lifebuoy light, liferaft light), Immersion suits, Lifejackets, Searchlight for lifeboat and rescue boats, Hydrostatic release units, Sound signaling(Bell,Gong), Embarkation ladders, Pilot ladder, Thermal protective aid, Sacrificial anode and so on. All the products have got the Type Approval Certificate issued by CCS and some of them has been attested by EC, GL, RS, USCG, ABS, BV. Our products own patent. The 15ppm Marine Oil Water Separator and Sewage Treatment Plant have been obtained Type Approval Certificate from CCS and IMO Circular.

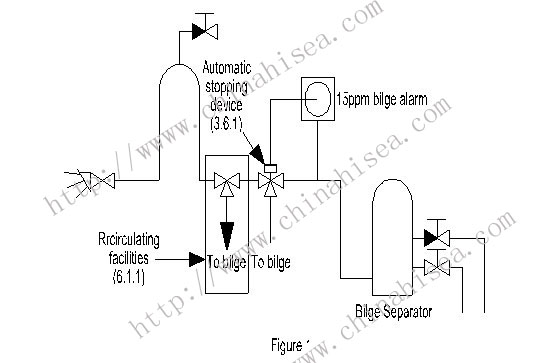

3. Marine Oil Water Separator (OWS) Principle:

The Oil Water separator adopts the combination of 1st stage, cone plate gravity and coalesce separation; 2nd stage, fiber filter and 3rd stage, membrane permeation in order to make the treated bilge water to reach the requirements of discharge standard of the resolution of IMO MEPC.107 (49).

As showing inthe enclosed drawing,bilge water comes into the 1st stage coalescer separator, because of the suction of the Feeding pump, that is in a vacuum negative pressure, and it effectively prevents the problem that the bilge water is difficult to be separated because of the emulsion caused by feed pump under pressure. The liquid coming out of Feeding pump is adsorbed and filtered by the 2nd stage fiber filter, and then goes into the 3rd stage membrane to reach the discharge standard.

There is a 15ppm bilge alarm in the ship cabin to measure the oil content of effluent. If it finds that the oil content of effluent is in an excess of limit, the oil content meter can make order to switch turn it into the 3rdstage, membrane treatment process.

The oil content meter will give an alarm if finds the oil content of effluent is above limit, and the unqualified water pneumaticthree-wayvalveVS6is opened automatically, so that the unqualified water is return to bilge, not to the overboard.

4. The 15ppm Bilge Alarm Device:

The oily water separating system is equipped with the 15ppm oil content alarm device OMD 2005, type tested and approved in accordance with IMO Resolution MEPC.107 (49).

The new resolution requires:

The 15ppm Bilge Alarm should record date, time alarm status and operating status of the 15ppm Bilge Separator. The recording device should also store data for at least eighteen months and should be able to display or print a protocol for official inspections as required. In the event that the 15ppm Bilge Alarm is replaced, procedures should be put in place to ensure the recorded data remain accessible on board for 18 months.

To prevent tempering with the 15ppm Bilge Alarms, the following precautions should be taken:

• Every access of the 15ppm Bilge Alarm beyond the essential requirements of paragraph 4.2.8 requires the breaking of a seal.

• The 15ppm Bilge Alarm should be so constructed that the alarm is always activated whenever clean water is used for cleaning or zeroing purposes.

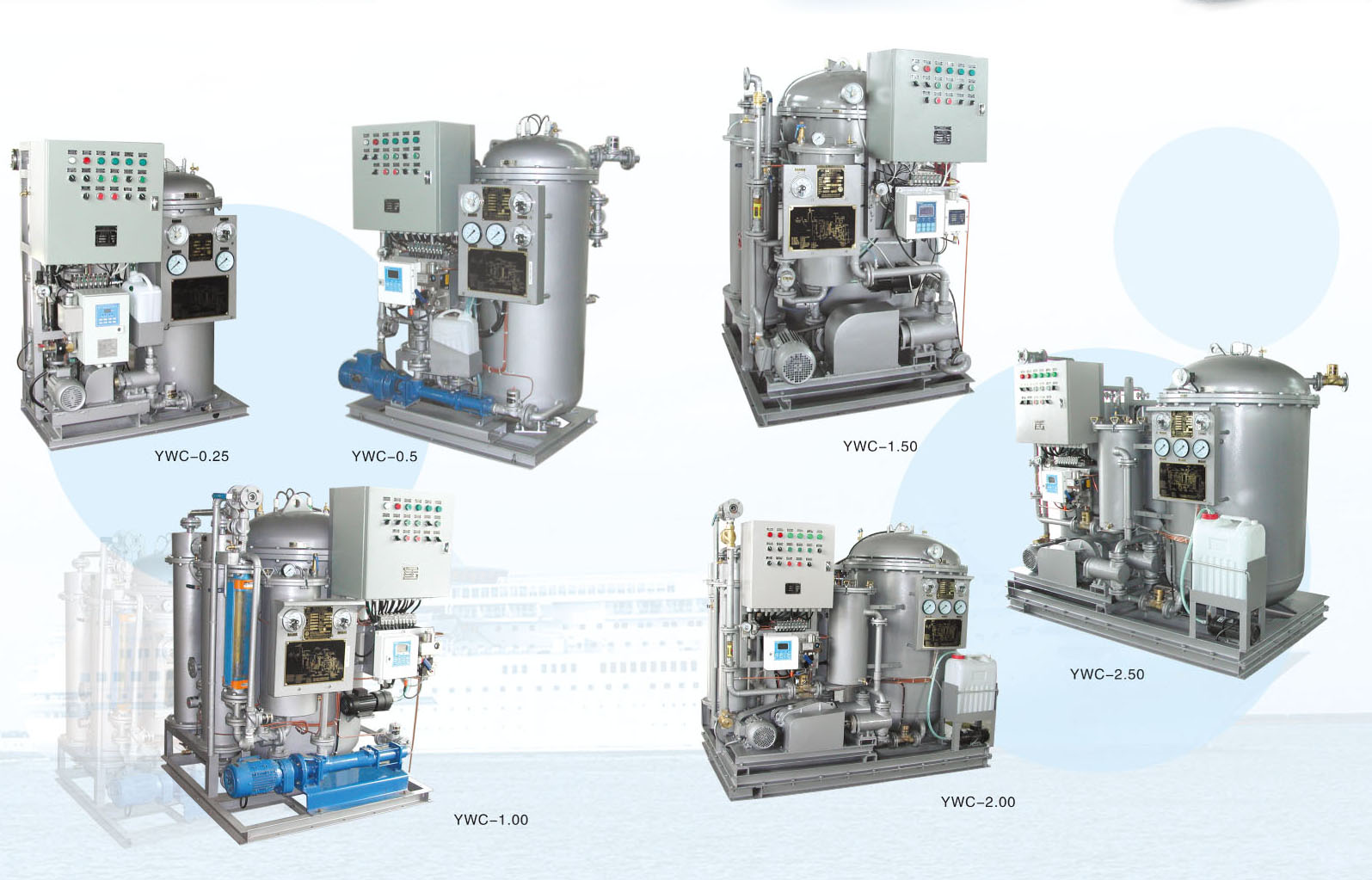

5. Marine Oil Water Separator Technical Data:

|

Type Technical Specifications |

YWC- |

|||||||||||

|

0.25 |

0.50 |

1.00 |

1.50 |

2.00 |

2.50 |

3.00 |

4.00 |

5.00 |

||||

|

Rated capacity(m3/h) |

0.25 |

0.50 |

1.00 |

1.50 |

2.00 |

2.50 |

3.00 |

4.00 |

5.00 |

|||

|

Oil content of the discharged water |

≯15ppm |

|||||||||||

|

Power of the electric heater(kw) |

1kw |

3kw |

6 |

6 |

6 |

6 |

6 |

12 |

12 |

|||

|

Electrical System |

AC 380V/50Hz/3φ, AC 415V/50Hz/3φ, AC 440/60Hz/3φ, AC 480V/60HZ/3φ (optional) |

|||||||||||

|

Power of the electric motor |

0.37kw |

0.55kw |

0.75kw |

1.1kw |

1.1kw |

1.5kw |

1.5kw |

2.2kw |

2.2kw |

|||

|

Suction head |

≯6m-H2O |

|||||||||||

|

Pressure of the discharged water |

5-10m-H2O |

|||||||||||

|

Outline Dimension(L×W×H)(mm) |

1000×600 ×1250 |

1100×690 ×1460 |

1050×1000 ×1620 |

1100×1130 ×1650 |

1900×1120 ×1700 |

1900×1120 ×1900 |

1700×1500 ×1900 |

2280×1700 ×1900 |

2590×2000 ×1900 |

|||

|

base |

5# |

6# |

6# |

6# |

8# |

8# |

8# |

10# |

10# |

|||

|

Weight |

Dry Weight |

400 |

600 |

800 |

1060 |

1260 |

1500 |

1800 |

2100 |

2500 |

||

|

|

Wet Weight |

550 |

900 |

1200 |

1650 |

2260 |

2800 |

3200 |

3900 |

4600 |

||

|

Applicable Vessel (KDWT) |

<1 |

1-5 |

5-10 |

10-30 |

30-50 |

50-100 |

100-200 |

100-300 |

>300 |

|||

6. Marine Oil Water Separator Certificate:

7. Marine Oil water Separator Showing Room:

Society certificates

CONTACT WITH US NOW